Motek/Bondexpo 2024 is Ready for Take-Off

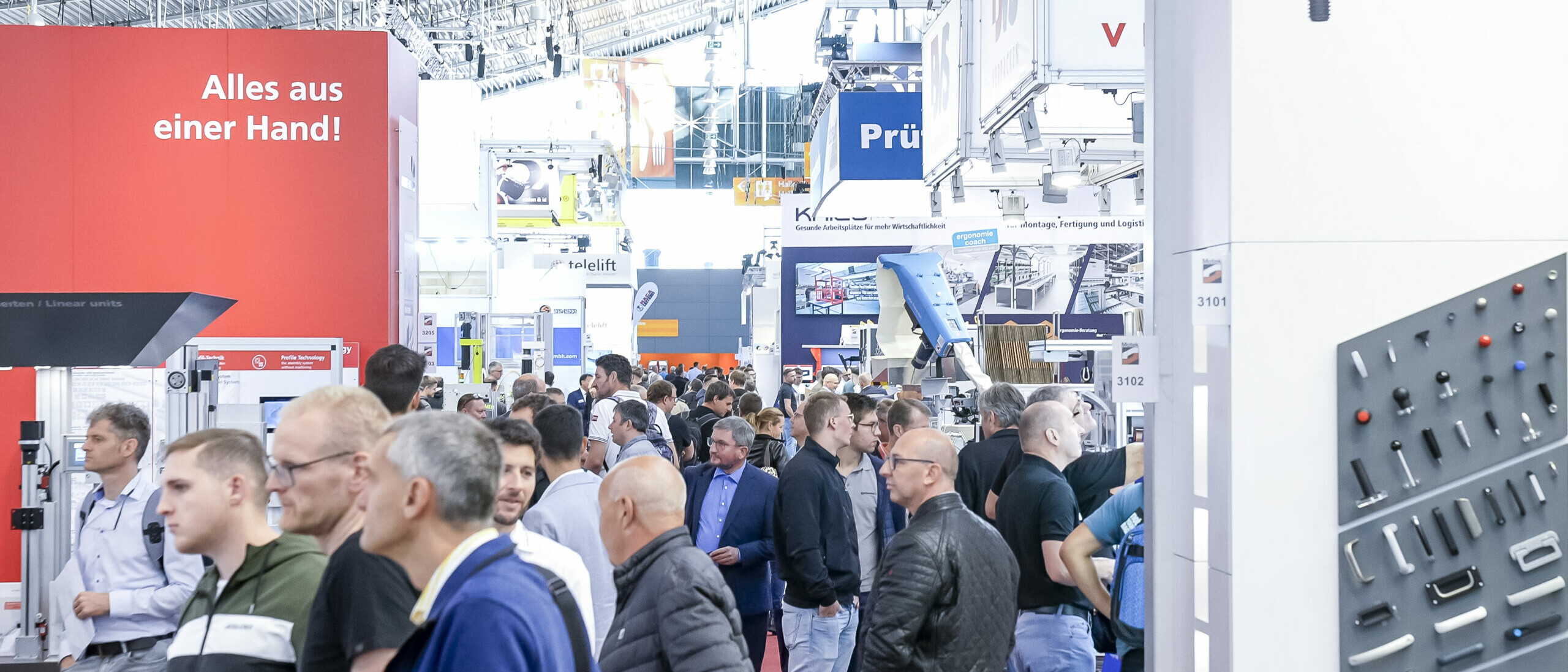

The Motek/Bondexpo technology and business platform is ready to go. Suppliers and users of production automation systems will meet in Stuttgart for the traditional autumn highlight from the 8th through the 11th of October, 2024. It’s essential for the industry to get fit for the future. The trade fair double-header will be flanked by an impressive, world-class supplementary programme.

“We’re ready to go,” announces Rainer Bachert, longstanding Motek/Bondexpo project manager. “We look forward to welcoming 400 exhibitors to halls 3, 5 and 7 in Stuttgart from the 8th through the 11th of October, 2024. We’ll witness exciting, forward-looking innovations in the field of production automation,” says Bachert. Efficiency, economy, the conservation of resources and the shortage of qualified personnel will be highlighted in all of the trade fair’s main thematic areas including production components and systems, assembly assistance systems and workstation equipment, solutions for easy implementation and commissioning, object recognition and image processing for inline parts detection and modern bonding technologies. “These factors continue to dominate as the driving force behind automation. Getting started with automation technologies has never been easier than it is now, even for small and mid-sized companies,” says project manager Bachert.

Digitalisation for Parts Feeding, Disentangling and Sorting as Well

Feed systems are indispensable for automation in assembly and production. A diverse range of components, parts, assemblies and end-products have to be fed and discharged in individualised configurations for production processes – a key step in manufacturing operations. RNA is one of the suppliers for this Motek focal point, and their booth will feature a consistently digital design this year. Expert visitors will discover a variety of real-world examples on various touchscreens as well as digital, reproducible feed systems. Users can use simulation programmes for actuator coordination and parts simulation in order to digitally validate their feed systems during the design phase, before the actual production of parts and components begins.

Mafu, another feed technology specialist, will showcase a broad range of conveyor solutions and will also bring new products from its recently launched screwdriving technology portfolio along to this year’s Motek/Bondexpo. Motek exhibitor Asyril also offers flexible feed solutions for state-of-the-art separation of bulk parts. They’re designed for easy integration and shorter throughput times for the separation of bulk materials in order to reduce overall production costs. For example, in combination with an intelligent image processing system, 3-axis vibration technology facilitates the separation of components of different sizes – even extremely small parts. Together with the intuitive EYE+ smart control system, the Asycube feed system and the Asyfill parts bunker offer remarkable versatility, especially in high-mix, low-volume production environments.

Integration of Software Solutions in Manual Assembly Operations

Workstation systems and equipment for manual assembly are also key topics at Motek. For example, Bott is focussing on the integration of software in manual assembly. Together with Assemblio, the company is presenting software for efficient assembly planning and the automated preparation of assembly instructions. Expert visitors are offered practical presentations, workshops and panel discussions as part of a separate supplementary programme at the company’s trade fair booth. Speakers include experts from leading companies and institutions who focus on process optimisation in production and assembly.

Topics covered by the programme include the practical implementation of AI and cross-system networking.

Manual assembly combined with modern image processing will be the subject of a keynote talk held by Björn Riechers, managing director of RK Rose+Krieger, at the opening press conference. His presentation is being eagerly awaited.

Automatic Parts Detection and Inspection Tasks with AI

Production and quality assurance are merging because to an ever-greater extent, testing processes are taking place inline during production. This significantly improves production performance, but at the same time it presents challenges for inspection and testing technologies. At Cambrian Robotics, for example, expert visitors can experience a 3D vision system for robots that uses AI, thus making it possible to recognise objects by means of a camera and execute complex tasks in the production environment. With its trevista Line Scan system, AIT Goehner will exhibit a solution for highly demanding surface inspection applications. The inspection system makes use of line scan technology in combination with Cognex’s shape-from-shading process for high-speed generation of optimised images. This technology helps to minimise waste and thus conserve resources.

Highly Promising Supplementary Programme with Lots of Artificial Intelligence

Motek/Bondexpo 2024 will once again be augmented by a world-class supplementary programme. It will offer in-depth information and additional opportunities for a personal exchange amongst industry experts. As is the case every year, Pilz’s expert forum on Safety + Security in Automation will be held again this year. Taking place on the first day of the trade fair (8 October 2024), the forum serves as a coveted meeting place for experts from associations, science and industry who want to find out more about trending topics regarding safe automation and machine safety. Attention will be focused on practice-oriented presentations dealing with safety and security in machine manufacturing, safe production, new machinery regulations and corporate sustainability.

The theme of the presentation forum on the second day of the trade fair, beginning at 9:30 a.m. on the 9th of October, is “No Need to Fear AI – Exploit Potential and Stay Competitive”. The presentations are targeted at companies and specialists who want to analyse potential applications and examine the challenges of AI in industry. Visitors will benefit from a deeper understanding of the opportunities offered by AI and will learn about practical solutions.

Presentations held by Fraunhofer on the 10th October will also focus on AI. Beginning at 9:40 a.m., the Fraunhofer IPA will speak on the subject of “AI-based robotics – how can production companies get up and running?”. Afterwards, beginning at 10:30 a.m., the Fraunhofer Institute for Cognitive Systems IKS will discuss “Flexible Quality Control: Solutions for the Challenges of AI-based Automation”.

The comprehensive agenda of the Exhibitor Forum in hall 5 includes presentations on revolutionising robotics, AI in production, sustainability as an economic success factor for the automation industry, digitalisation of production and flexible quality control. The programme has a clear thematic focus and is targeted at production automation specialists.

www.motek-messe.de/en/trade-fair-program/

By purchasing a single ticket, trade fair visitors gain access to six trade fairs taking place simultaneously in Stuttgart – all visitors are cordially invited to take advantage of these synergies. “Expert visitors will enjoy an efficient and informative trade fair experience at Motek/Bondexpo from the 8th through the 11th of October, 2024,” assures Bettina Schall, managing director of Schall trade fair promoters. “There’s no substitute for personal discussion and professional dialogue on an equal footing,” says the managing director, “which is why we’re looking forward to seeing everyone again in Stuttgart, and to many interesting encounters!”

Keep yourself well informed!

Links to websites:

www.motek-messe.de/en/

www.bondexpo-messe.de/en/

Information on the trade fair and industry:

www.motek-messe.de/en/news-stories/

Register for our newsletter:

www.motek-messe.de/en/#newsletter

Follow us on LinkedIn:

www.linkedin.com/company/motek-messe/

62 Years of Trade Fairs for Markets – Schall Trade Fairs’ Recipe for Success

Schall has developed successful business platforms with internationally recognised trade fairs for quality assurance (Control), optical technologies, components and systems (Optatec), stamping technology (Stanztec), automation in production and assembly (Motek), bonding technology (Bondexpo), plastics processing (Fakuma), sheet metal working (Blechexpo) and joining technology (Schweisstec). This has given rise to entirely new markets in various sectors, whose protagonists are distinguished by tremendous innovative strength, comprehensive systems competence and practical application solutions.